Senior Design-2023

Valencia College

TESTING & RESULTS

HIGH-LEVEL Requirement #1:

The product shall maintain the temperature of computers 10-20°F lower than conventional Air-cooling solutions.

We began this test by pressurizing the capsule and submerging it underwater. We conducted the same test as previously performed during our mock tests, utilizing identical values for time and frequency to overclock the computers. The resulting data was graphically represented, showcasing temperature differentials between the product and conventional air-cooling solutions. The video below demonstrates the procedure followed by the resulting graphs.

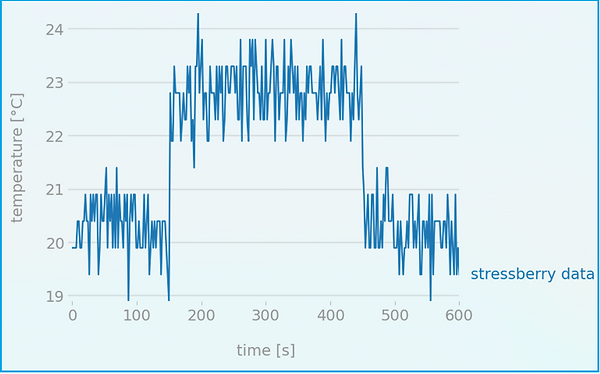

CPU1 Stress Test Results

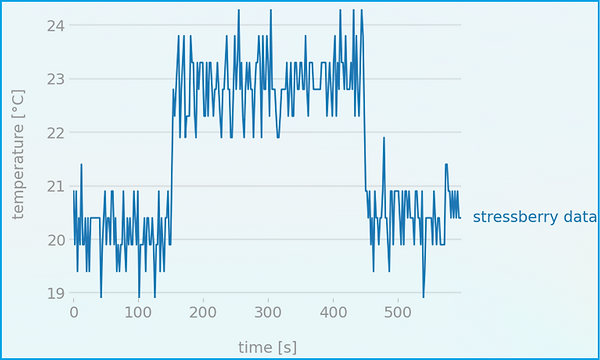

CPU2 Stress Test Results

Conventional Air cooling Stress Test Results

Comparing these results with those previously obtained using conventional air cooling methods, we achieved a peak temperature reduction of 23.8°C or 42.8°F. The table provided below presents the list of tests along with their respective results.

HIGH-LEVEL Requirement #2:

The product shall ensure that water is effectively kept out of the capsule housing the electrical components.

To validate this engineering requirement we recorded footage over 24 hours, keeping the capsule submerged underwater while simultaneously monitoring the humidity and air pressure. The results were positive, with no increase in humidity and no air pressure lost. The video below is a timelapse of the 24 hour recording.

HIGH-LEVEL Requirement #3:

The product shall allow the computers inside the capsule to communicate with the client PC.

To fulfill this requirement, we relied on establishing a Local Area Network over Ethernet, as Wi-Fi communication is not viable underwater. To test and validate connectivity, the following video demonstrates the use of VNC and a tool called Advanced IP Scanner to showcase the network connection between the computers. It's crucial to note that Wi-Fi capabilities were disabled in all four devices during testing to ensure a local area network over Ethernet is used. The video below demonstrate the procedure taken for the successful validation of this engineering requirement.

MID-LEVEL Requirement #1:

The product shall grant the user the ability to remotely monitor and control capsule pump operation, monitor air temperature, read humidity levels and display alerts.

This Engineering requirement was validated in three separate parts for better clarity. The following video will demonstrate the air pressure monitoring and failure system in the event of pressure loss.

In the following video, the humidity and air-pressure monitoring will be validated by administering hot air to the capsule.

Finally, pump selection using the user interface is demonstrated.

MID-LEVEL Requirement #2:

The product shall Incorporate redundancy measures to ensure continued operation in case of component failures.

In the following video, we demonstrate the system's capability to remain operational even after one of the pumps has failed or stopped operating. Furthermore, in the event of a secondary pump failure, the system will make one final attempt to start the primary pump before notifying the user that the system is non-operational. We will simulate each pump failure by removing power from the pumps.

LOW-LEVEL Requirement :

The product shall operate at a very low noise level.

To evaluate the requirement of operating at a very low noise level, we began by measuring the ambient noise level to establish a baseline, which resulted in around 50dB. Following this, we operated the equipment and measured the noise level produced. The results showed that while our system was running, the noise level increased by only 7dB meeting our requirement to stay below 35dB. The video below demonstrates the procedure taken.